|

|

- Our management team has over 10 years of experience in die casting and the total solutions process. It is a strong leadership focused on motivation, innovation, and customer service.

- ISO-9002 certification was awarded by DNV in May, 1998, QS-9000 certification was awarded by DNV in September, 2001 , and TS16949 certification was awarded by DNV in 2007.

- The yield rate of our aluminum products is 90% and is 60-70% for our magnesium products.

- Utilizing CAD/CAE/CAS, structural parts can be produced with a thickness of 0.8 ~ 1.0 mm, while external parts can be produced with a thickness of 1.0 ~ 1.2 mm.

- A highly efficient magnesium scrap recycling process is available on site, enabling us to reduce the cost of materials.

- The ANOMAG process, licensed from a New Zealand company, is an environmentally friendly non-chrome, non-heavy metal based coating system for magnesium products.

- Our tenet is for T1 to be completed in 45~50 days to ensure our customer's timely entry into their markets.

- Gatetech prides itself in its superb developmental capabilities, its world class service and its industry leading processes.

|

|

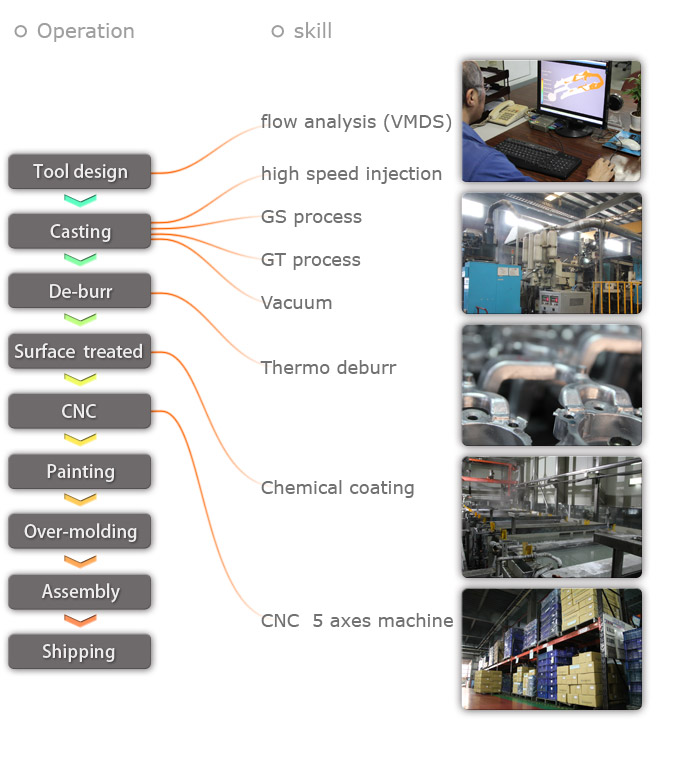

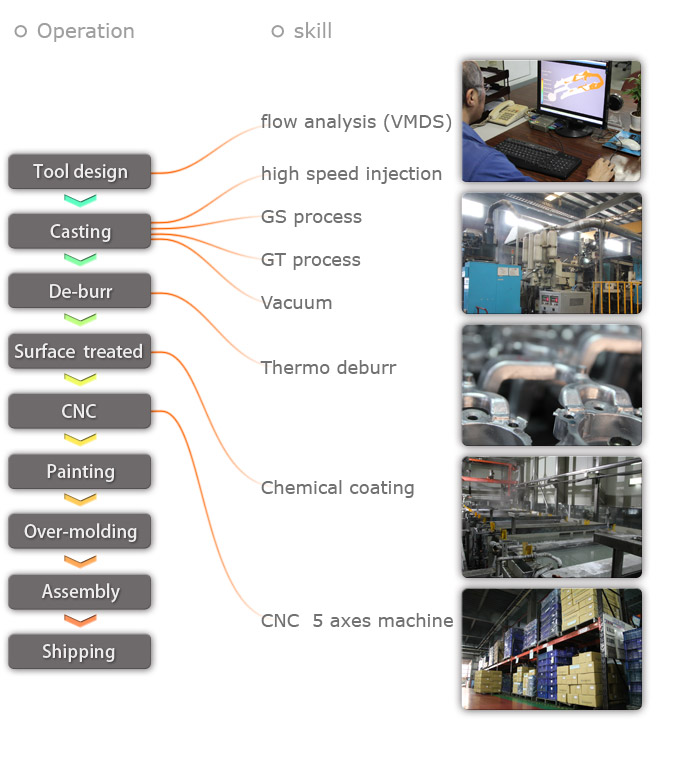

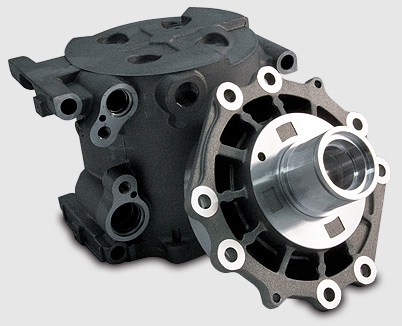

Total Solution for Mg and Al alloys die casting parts: Provide customer one- stop shopping service , besides die casting、 machining process ,also can provide surface treatment 、painting and assembly service. Total Solution for Mg and Al alloys die casting parts: Provide customer one- stop shopping service , besides die casting、 machining process ,also can provide surface treatment 、painting and assembly service. |

|

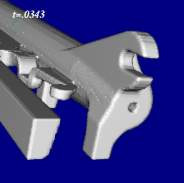

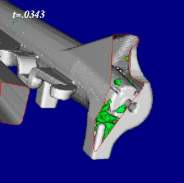

| Analysis flow pattern |

| Technology |

Analysis flow pattern、velocity 、solidification, and then offer a physical design solution before mold installed. |

| Methods |

|

| Top-quality |

- Good rate reliability.

- Try frequency reduce.

- Develop period shorten.

|

| Compare |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| Analysis feeding |

Flow pattern analysis |

Cut piece check |

|

|

|

|

|

|

| |

|

|

H/P injection H/P injection |

| Technology |

Good filling & surface for thinner part by high pressure and high speed injection. |

| Methods |

|

| Top-quality |

|

| Compare |

|

|

|

|

|

|

| |

|

|

Vacuum Vacuum |

| Technology |

Vacuum installation on cavity. |

| Methods |

|

| Top-quality |

|

| Compare |

|

|

|

|

|

|

| |

|

|

GS process GS process |

| Technology |

Before solidification , add pressure to reduce shrinkage risk, suitable for thicker wall parts, also can achieve better high pressure resistant. |

| Methods |

|

| Top-quality |

|

| Compare |

|

|

|

|

|

|

| |

|

|

GT process GT process |

| Technology |

Using sudden burn to reduce cavity air to improve porosity risk. |

| Methods |

|

| Top-quality |

|

| Compare |

|

|

|

|

|

|